Custom-Designed Screw Conveyors That Are Built to Last

Screw conveyors from Materials Handling Equipment (MHE) can be custom engineered and manufactured to meet your individual requirements. This means you won’t have to worry about the additional expense of purchasing a standard-built screw conveyor that doesn’t fit your exact requirements and has minimal design and operation abilities, which could end up costing you more over the long term.

MHE Offers Unmatched Industry Experience

Since 1927, MHE has been engineering and manufacturing screw conveyors that not only meet CEMA standards—we were a key member during the development of many of the standards—but also actually exceed those standards, as we have continuously improved our designs to meet the ever-expanding needs of industry. MHE’s many decades in business has established us as one of the most respected and trusted names in the industry.

What Makes Our Screw Conveyors Different?

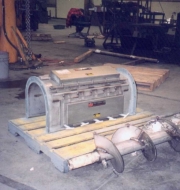

The benefits of choosing MHE for your screw conveyor go way beyond economics. Simply put, our heavy-duty conveyors are recognized as some of the most durable options available. We utilize a wide array of custom drives as well as components made from wear-resistant alloys to ensure that our conveyors will be able to perform reliably in the harshest conditions imaginable, including environments where they’ll be subjected to extreme abrasion, corrosion, or temperatures. In fact, we’re proud to note that many of our custom conveyors are still going strong more than 50 years after initial delivery.

Some of the features of MHE screw conveyors are:

- Capacities of up to 300 TPH

- Diameters of up to 6 feet

- Lengths up to 300 feet

- Inclined models up to 60 degrees

- Heat resistance of up to 2200 degrees Fahrenheit

- Jig-welded construction for precise alignment

- Break-formed troughs and heavy-duty formed flanges

- Tubular, U-type, V-type, drop bottoms, box type, and split troughs

- Standard, ribbon, cut, and paddle flights

- Hardfacing 2-3-4 bolt coupling shafts, quick keys, 4140 shafts

- Easy maintenance from top and ends with unique access

- Longer service life thanks to heavy-duty Ni-Hard bearings

Screw conveyors from MHE—great for ash handling—come in many categories, including sectional; ribbon; cut-and-fold, and serrated with quarter-, third-, half-, and full-pitch, as well as double flighting and hardfacing. MHE custom designs each screw conveyor for exacting requirements. Our conveyors can also be used for the efficient transference of cereal grains, wood chips, biomass, municipal solid waste, aggregates, cement, clinker, gypsum, phosphate, and many other forms of bulk material.

From design all the way through to service, MHE will work directly with you to ensure your continued satisfaction with your screw conveyors. We’ll start by meeting with your engineers to learn about your specific requirements and goals and to view the location the screw conveyor will occupy. Once manufacturing has been completed and the conveyor has been installed, we’ll ensure that your employees are trained on its operation and safety features. Additionally, our Critical Care team will be standing by to provide assistance should an issue ever occur.

If you are interested in contacting MHE so you can receive more information about the heavy-duty screw conveyors we manufacture for industrial operations throughout the U.S., click here today.