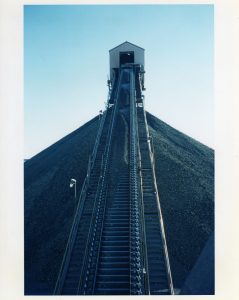

Efficient material handling is critical in the cement industry, where large volumes of abrasive materials must be transported throughout the production process. Bucket elevators play a key role in this operation by providing a reliable and efficient way to move raw materials, clinker, and finished cement between processing stages. These high-capacity conveyors enable vertical transportation, helping cement plants streamline their operations while minimizing manual handling and potential material loss.

Upgrading the Cement Handling Process

The cement industry relies on efficient, high-speed material handling to maintain consistent production rates. Bucket elevators contribute significantly to this process by lifting materials such as limestone, gypsum, and clinker between processing stations. These conveyors are designed to handle both fine and coarse materials, making them an excellent solution for moving raw ingredients into grinding mills or transferring processed cement to storage silos.

Some of the key benefits of using bucket elevators in cement production include:

- Increased productivity – By automating the vertical transportation of bulk materials, bucket elevators help plants operate at a faster pace without bottlenecks.

- Improved safety – By reducing the need for manual handling, bucket elevators lower the risk of workplace injuries associated with lifting and transporting heavy materials.

- Minimized material degradation – Unlike some conveyor systems that may cause material breakdown, bucket elevators are designed to move cement-related materials with minimal spillage or degradation.

- Space optimization – Since bucket elevators transport materials vertically, they save valuable floor space, allowing cement plants to optimize their layout for maximum efficiency.

With the right bucket elevator in place, cement manufacturers can significantly enhance their material handling capabilities, leading to smoother operations and higher overall output.

The Advantages of Custom Bucket Elevators

Not all bucket elevators are created equal, and in industries like cement production, where materials are abrasive and heavy, a one-size-fits-all approach rarely delivers the best results.

Custom bucket elevators provide a variety of advantages over standard, off-the-shelf options, including:

- Tailored design – Custom-manufactured bucket elevators can be designed to fit the specific needs of a cement plant, accommodating factors like height restrictions, material types, and processing speeds.

- Durability for harsh environments – Cement plants require rugged equipment that can handle extreme operating conditions. Custom-built bucket elevators are engineered to withstand elevated temperatures, abrasive materials, and continuous operation.

- Longer service life – Investing in a custom solution reduces the need for frequent repairs and replacements, ultimately lowering maintenance costs and downtime.

- Optimized efficiency – A bucket elevator designed specifically for a cement plant’s workflow will operate more efficiently than a generic model, improving throughput and reducing energy consumption.

Custom fabrication allows cement plants to implement bucket elevators that are built for their exact requirements, leading to more reliable performance and greater long-term savings.

Heavy-Duty Bucket Elevators from Materials Handling Equipment

Materials Handling Equipment (MHE) provides durable and long-lasting bucket elevators for the cement industry. We have more than a century of experience in manufacturing industrial-grade conveyors, so we design and fabricate bucket elevators that outperform standard options.

MHE bucket elevators are built using wear-resistant materials, making them capable of handling the extreme demands of cement production. We specialize in custom solutions, tailoring each conveyor to fit the precise specifications of our clients. Whether a plant needs a high-capacity conveyor for moving large volumes of raw materials or a compact elevator for tight spaces, our team delivers solutions that enhance efficiency and longevity.

We Offer Custom Solutions for Cement Handling

A well-designed bucket elevator is essential for maintaining smooth and efficient bulk material handling in a cement plant. At MHE, we don’t offer cookie-cutter solutions—we manufacture bucket elevators that are built to handle the specific challenges of cement production.

Learn More

If you’re looking for a reliable, heavy-duty bucket elevator for your cement plant, Materials Handling Equipment has the expertise needed to deliver the right solution. Contact us today to learn more about how our custom bucket elevators can enhance the efficiency of your cement production process.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Pan conveyors are an indispensable tool for various industries, including cement manufacturing and power generation. Their ability to efficiently transport bulk materials, even under challenging conditions, makes pan conveyors a versatile solution for operations requiring reliability and productivity. By integrating pan conveyors into your facility, you can enhance throughput, reduce maintenance downtime, and optimize overall performance.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials.

Innovation drives progress in every industry, and the world of conveyor technology is no exception. As businesses strive to maximize efficiency and productivity, advancements in conveyor systems are becoming essential. Beyond increasing profits, modernizing conveyors supports sustainability by reducing energy consumption and waste. In 2025, emerging conveyor technology trends promise to revolutionize the way industries handle bulk materials. Many industrial operations rely on bucket elevators to handle bulk materials efficiently. From moving materials vertically to transporting them across production lines, these systems are essential in industries like agriculture, mining, and manufacturing. However, choosing the right bucket elevator depends on your specific operational needs. Two common types are continuous and centrifugal bucket elevators, each offering unique advantages.

Many industrial operations rely on bucket elevators to handle bulk materials efficiently. From moving materials vertically to transporting them across production lines, these systems are essential in industries like agriculture, mining, and manufacturing. However, choosing the right bucket elevator depends on your specific operational needs. Two common types are continuous and centrifugal bucket elevators, each offering unique advantages.

Industrial plants operating in severe conditions need equipment that can handle the harshest environments. Special-service conveyors play a crucial role in these facilities, where durability, reliability, and longevity are paramount. For plants dealing with extreme temperatures, heavy loads, or corrosive materials, custom-engineered conveyors made from wear-resistant materials are vital to maintaining continuous operations.

Industrial plants operating in severe conditions need equipment that can handle the harshest environments. Special-service conveyors play a crucial role in these facilities, where durability, reliability, and longevity are paramount. For plants dealing with extreme temperatures, heavy loads, or corrosive materials, custom-engineered conveyors made from wear-resistant materials are vital to maintaining continuous operations. Manufacturing plants are increasingly seeking ways to improve sustainability and reduce their carbon footprint, and one of the more effective solutions is the use of custom conveyors. By integrating eco-friendly conveyors into their operations, manufacturers can optimize material handling processes, minimize energy consumption, and enhance overall efficiency. Custom conveyors, designed to meet the specific needs of a facility, can play a vital role in reducing environmental impact while maintaining or increasing production levels.

Manufacturing plants are increasingly seeking ways to improve sustainability and reduce their carbon footprint, and one of the more effective solutions is the use of custom conveyors. By integrating eco-friendly conveyors into their operations, manufacturers can optimize material handling processes, minimize energy consumption, and enhance overall efficiency. Custom conveyors, designed to meet the specific needs of a facility, can play a vital role in reducing environmental impact while maintaining or increasing production levels.