In today’s competitive manufacturing landscape, improving efficiency and profitability is more important than ever. Manufacturing plants are continuously searching for ways to streamline their processes, reduce downtime, and maximize output. One of the most effective solutions for achieving these goals is the implementation of a well-designed conveyor system. Conveyor systems have become the backbone of modern manufacturing, playing a pivotal role in moving materials, products, and components seamlessly through the production line. By integrating advanced conveyor equipment into their operations, manufacturers can optimize workflow, minimize labor costs, and increase production speed—all of which contribute to greater profitability.

In today’s competitive manufacturing landscape, improving efficiency and profitability is more important than ever. Manufacturing plants are continuously searching for ways to streamline their processes, reduce downtime, and maximize output. One of the most effective solutions for achieving these goals is the implementation of a well-designed conveyor system. Conveyor systems have become the backbone of modern manufacturing, playing a pivotal role in moving materials, products, and components seamlessly through the production line. By integrating advanced conveyor equipment into their operations, manufacturers can optimize workflow, minimize labor costs, and increase production speed—all of which contribute to greater profitability.

The Growing Role of Conveyor Systems in Manufacturing

The role of conveyor systems in manufacturing has expanded significantly through the years. Originally used primarily for simple material handling tasks, conveyor systems are now integral to nearly every stage of the production process. With advancements in technology, conveyor systems have evolved to accommodate the complex needs of modern manufacturing plants. Whether it’s moving raw materials into production, transporting finished goods for packaging, or managing waste removal, conveyor systems are vital to maintaining a smooth and efficient workflow.

Custom conveyors, in particular, are becoming increasingly popular as manufacturers recognize the need for systems tailored to their specific processes. These custom solutions are designed to handle unique materials, accommodate specific plant layouts, and meet the demands of specialized production lines. As manufacturing processes become more complex and varied, the demand for versatile and reliable conveyor systems continues to grow.

Types of Industrial Conveyors That Can Improve Manufacturing Workflow

To improve workflow in manufacturing, you must choose the right type of conveyor system. Each type of industrial conveyor is designed to meet specific needs and selecting the right one can significantly enhance operational efficiency. Options include:

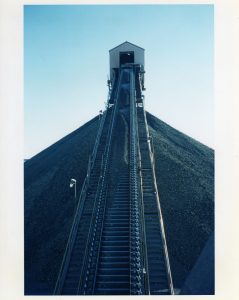

- Apron conveyors – Ideal for handling heavy, abrasive materials, apron conveyors are designed to withstand harsh environments. These conveyors are perfect for industries such as mining, cement production, and chemical production.

- Drag conveyors – Used for handling bulk materials like grain, ash, and finished cement, and cement clinker, drag conveyors efficiently move materials over long distances while minimizing product degradation.

- Bucket elevators – This vertical conveyor system is perfect for lifting bulk materials to different heights within the production facility, making it ideal for industries that utilize grain, chemicals, coal, ash, biomass wood pellets, frac sand, and aggregates.

- Screw conveyors – Commonly used for transporting granular or semi-solid materials, screw conveyors are versatile and can be used in various industries, including agriculture, cement, wall board, power, and food processing.

- Pan conveyors – Suitable for handling hot, abrasive, or sticky materials, pan conveyors are often used in heavy-duty applications in steel mills, foundries, and cement production facilities.

- Belt conveyors – One of the most versatile conveyor systems, belt conveyors are used in a wide range of industries to move everything from raw materials to finished products.

Heavy-Duty Conveyors From Materials Handling Equipment

When it comes to heavy-duty conveyor systems, Materials Handling Equipment (MHE) stands out as a leader in the industry. We have cultivated a reputation for designing and manufacturing custom conveyors that meet the most demanding specifications, and we offer a range of conveyor equipment that is built to last.

What sets MHE apart is our commitment to delivering custom conveyor solutions. Each system we produce is tailored to the specific needs of the client, ensuring that the conveyor equipment integrates seamlessly with existing processes. This level of customization, combined with MHE’s decades of experience, makes us the best choice for manufacturers looking for reliable and efficient conveyor systems.

Optimize Your Production

If your manufacturing plant is looking to improve efficiency and increase profitability, investing in a custom conveyor system from Materials Handling Equipment is the right choice. Contact MHE today to learn more about our heavy-duty conveyor solutions and how they can help streamline your production processes.

For waste management facilities that are interested in using heavy-duty conveyor systems to improve operational workflow, understanding the potential benefits and return on investment is crucial. Integrating a conveyor system can seem like a significant upfront investment, but the long-term efficiency gains often outweigh the initial costs. That’s because these systems are engineered to streamline operations, reduce labor costs, and enhance overall efficiency in waste management processes.

For waste management facilities that are interested in using heavy-duty conveyor systems to improve operational workflow, understanding the potential benefits and return on investment is crucial. Integrating a conveyor system can seem like a significant upfront investment, but the long-term efficiency gains often outweigh the initial costs. That’s because these systems are engineered to streamline operations, reduce labor costs, and enhance overall efficiency in waste management processes. In the heart of every industrial plant that deals with heavy loads and rigorous operations, the need for reliable and consistent material handling solutions is vital. For some operations, a heavy-duty pan conveyor system can provide the robust support needed to ensure seamless operations. Designed to withstand the toughest conditions, these conveyors are ideal for facilities looking to enhance efficiency and reduce downtime.

In the heart of every industrial plant that deals with heavy loads and rigorous operations, the need for reliable and consistent material handling solutions is vital. For some operations, a heavy-duty pan conveyor system can provide the robust support needed to ensure seamless operations. Designed to withstand the toughest conditions, these conveyors are ideal for facilities looking to enhance efficiency and reduce downtime. Warehouse automation refers to the use of technology and machinery to perform storage and movement of goods with minimal human intervention. This innovative approach is transforming industries by increasing efficiency, reducing costs, and enhancing the accuracy of operations. Key sectors reaping these benefits include manufacturing, retail, and distribution. By automating processes, businesses can handle larger volumes with greater precision, leading to improved efficiency and productivity.

Warehouse automation refers to the use of technology and machinery to perform storage and movement of goods with minimal human intervention. This innovative approach is transforming industries by increasing efficiency, reducing costs, and enhancing the accuracy of operations. Key sectors reaping these benefits include manufacturing, retail, and distribution. By automating processes, businesses can handle larger volumes with greater precision, leading to improved efficiency and productivity. In the realm of agro-processing, your choice of conveying equipment can significantly impact your plant’s operational efficiency and product quality. Bucket conveyors, also known as bucket elevators, stand out as a superior choice for various heavy-duty agricultural applications thanks to the many unique advantages they offer when compared to other types of industrial conveyors.

In the realm of agro-processing, your choice of conveying equipment can significantly impact your plant’s operational efficiency and product quality. Bucket conveyors, also known as bucket elevators, stand out as a superior choice for various heavy-duty agricultural applications thanks to the many unique advantages they offer when compared to other types of industrial conveyors. In the paper and pulp industry, efficiency is paramount. Every step of the production process must be optimized to ensure maximum output without compromising on quality. Advanced conveyor systems can play a crucial role in streamlining paper production. By utilizing customized conveyors designed for the unique requirements of the paper and pulp industry, companies can optimize their production process, improve efficiency, and reduce costs.

In the paper and pulp industry, efficiency is paramount. Every step of the production process must be optimized to ensure maximum output without compromising on quality. Advanced conveyor systems can play a crucial role in streamlining paper production. By utilizing customized conveyors designed for the unique requirements of the paper and pulp industry, companies can optimize their production process, improve efficiency, and reduce costs.

The agricultural industry relies heavily on industrial conveyors which, when used effectively, can optimize efficiency and ensure seamless operations. These conveyors can streamline the complex processes involved in handling, transporting, and processing crops. From the initial stages of planting and harvesting to the subsequent sorting, cleaning, and packaging, conveyors provide a continuous and controlled movement of agricultural goods.

The agricultural industry relies heavily on industrial conveyors which, when used effectively, can optimize efficiency and ensure seamless operations. These conveyors can streamline the complex processes involved in handling, transporting, and processing crops. From the initial stages of planting and harvesting to the subsequent sorting, cleaning, and packaging, conveyors provide a continuous and controlled movement of agricultural goods. In the world of industrial material handling, the choice between custom conveyors and off-the-shelf options can significantly impact long-term costs and operational efficiency. While you may save some time by choosing a ready-made conveyor for your plant, that’s where the benefits end, and you could be making a decision that will negatively impact your company’s productivity and flexibility.

In the world of industrial material handling, the choice between custom conveyors and off-the-shelf options can significantly impact long-term costs and operational efficiency. While you may save some time by choosing a ready-made conveyor for your plant, that’s where the benefits end, and you could be making a decision that will negatively impact your company’s productivity and flexibility. In the ever-evolving landscape of material handling, technological advancements have reshaped the industry, with robotics playing a pivotal role. However, while robotics has greatly impacted material handling in general, there are still applications for which traditional conveyor systems are better suited. Let’s explore the benefits and limitations of robotics when it comes to material handling.

In the ever-evolving landscape of material handling, technological advancements have reshaped the industry, with robotics playing a pivotal role. However, while robotics has greatly impacted material handling in general, there are still applications for which traditional conveyor systems are better suited. Let’s explore the benefits and limitations of robotics when it comes to material handling.