In the hectic world of industrial operations, efficiency is vital. The never-ending quest for increased productivity has paved the way for innovative solutions, and heavy-duty industrial conveyors have played a notable role. Material handling equipment has become an indispensable tool used by a wide array of industries, offering important benefits that elevate operational efficiency to new heights.

In the hectic world of industrial operations, efficiency is vital. The never-ending quest for increased productivity has paved the way for innovative solutions, and heavy-duty industrial conveyors have played a notable role. Material handling equipment has become an indispensable tool used by a wide array of industries, offering important benefits that elevate operational efficiency to new heights.

Optimizing Efficiency in Industrial Facilities

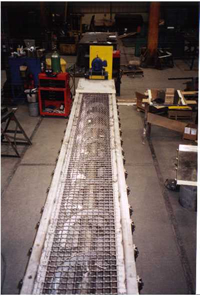

When it comes to handling substantial loads and maintaining seamless operations, heavy-duty industrial conveyors are second to none. These mechanical workhorses are specifically designed to transport bulky materials, components, and products within industrial setups. Their robust construction and high load-bearing capacities make them essential for optimizing production processes and reducing labor-intensive tasks.

Types of Heavy-Duty Industrial Conveyors

Different industries can benefit from the advantages of heavy-duty industrial conveyors by selecting from a range of specialized types, including:

- Belt conveyors, which can efficiently transport bulk materials over long distances and offer the most economical cost per foot

- Screw conveyors, which are ideal for handling dry, granular materials like cement and chemicals with accurate control of feed

- Chain conveyors, which are often used for heavier loads and at elevated temperatures with flexible installations

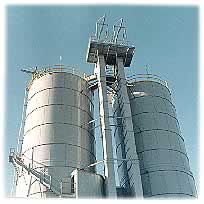

- Bucket elevators, which lift bulk materials vertically

- Apron and pan conveyors, which are designed to handle heavy, abrasive, and/or high-temperature materials in complex applications

Industries That Benefit From Heavy-Duty Industrial Conveyors

Several industries have enjoyed notable improvements in productivity because of the utilization of properly designed, heavy-duty industrial conveyors. They include:

- Agriculture – Conveyors help to efficiently transport crops and raw materials for processing, reducing manual labor and ensuring quicker processing.

- Cement – Conveyors handle raw materials and finished products, optimizing manufacturing processes and minimizing downtime.

- Chemicals – Conveyors allow for the safe transport of hazardous chemicals, streamlining production and reducing exposure risks for workers.

- Construction – Conveyors move heavy building materials effortlessly, enhancing construction site efficiency.

- Mining and minerals – Conveyors handle bulk materials, increasing extraction and processing efficiency in mines.

- Steel – Heavy-duty conveyors are used to transport raw materials and finished steel products, contributing to a smoother production process.

- Power and utilities – Conveyors can be used to elevate coal and biomass for power generation, enhancing energy production efficiency.

- Paper and pulp – Conveyors streamline paper production, reducing manual handling and increasing throughput.

Offering Undeniable Benefits

The use of heavy-duty industrial conveyors has been pivotal in elevated efficiency and productivity. Conveyors not only facilitate the seamless flow of materials but also improve overall operational efficiency, cost-effectiveness, and employee safety. By selecting from an array of conveyor types tailored to specific industry needs, businesses can optimize their workflows and boost output. From agriculture to paper, heavy-duty conveyors have helped transform all types of industries.

The Conveyor Manufacturing Experts

Materials Handling Equipment (MHE) has been the leading manufacturer of heavy-duty conveyors in the United States since 1927. We offer custom conveyors designed to meet specific demands, and we can adapt our product lines for a wide range of industries. Our expertise lies in the production of specialized conveyors designed for unique services. Our conveyors provide impeccable performance even in the most intense conditions, including extreme temperatures, abrasion, and corrosion.

Would you like to learn more about the heavy-duty conveyors we offer? If so, contact Materials Handling Equipment today to schedule a consultation.

Drag conveyors and screw conveyors are popular options for bulk material handling in a variety of industries, and while both might be able to accomplish a company’s goals, they’re not always interchangeable options. Drag conveyors and screw conveyors both offer advantages and disadvantages, and often the best option depends on the type of material being moved.

Drag conveyors and screw conveyors are popular options for bulk material handling in a variety of industries, and while both might be able to accomplish a company’s goals, they’re not always interchangeable options. Drag conveyors and screw conveyors both offer advantages and disadvantages, and often the best option depends on the type of material being moved. While you’re trying to choose between a drag conveyor and a screw conveyor for your plant, there’s one decision that should be easy. Materials Handling Equipment is the wise choice for any type of industrial conveyor, as we’ve been perfecting our manufacturing process since 1927. While many conveyor manufacturers offer standard models that lack modification, we deliver multiple types of screw and drag conveyors that are customized to meet the specific needs of our clients.

While you’re trying to choose between a drag conveyor and a screw conveyor for your plant, there’s one decision that should be easy. Materials Handling Equipment is the wise choice for any type of industrial conveyor, as we’ve been perfecting our manufacturing process since 1927. While many conveyor manufacturers offer standard models that lack modification, we deliver multiple types of screw and drag conveyors that are customized to meet the specific needs of our clients. There are plenty of options when it comes to conveyors for bulk material, and two of the most common are belt conveyors and apron conveyors. Both of these conveyor categories offer advantages and drawbacks, and if you’re trying to decide which will best fit your company’s needs, there are plenty of questions that you need to ask. Materials Handling Equipment (MHE) has been manufacturing heavy-duty conveyors for some of the largest industrial companies in the U.S. since 1927, so we’re uniquely qualified to compare and contrast these two options.

There are plenty of options when it comes to conveyors for bulk material, and two of the most common are belt conveyors and apron conveyors. Both of these conveyor categories offer advantages and drawbacks, and if you’re trying to decide which will best fit your company’s needs, there are plenty of questions that you need to ask. Materials Handling Equipment (MHE) has been manufacturing heavy-duty conveyors for some of the largest industrial companies in the U.S. since 1927, so we’re uniquely qualified to compare and contrast these two options. What Is a Screw Conveyor?

What Is a Screw Conveyor? Transporting items from point A to Point B is a common occurrence for almost any type of business and is often accomplished by manpower. However, when the “items” that need to be moved are heavy, dangerous, or difficult to contain and need to be moved continuously in large quantities, a conveyor comes into play. The use of conveyors for material handling has been occurring since as far back as 1795, when basic conveyor systems were used to move grains a short distance. By definition, a conveyor is any piece of mechanical equipment that moves materials from one location to another. In day-to-day business, this could be a belt that is used to sort packages, items coming off a production line, or luggage headed to an airplane cargo hold. For industrial purposes, however, conveyors are much more specialized and must be able to withstand many different types of environments.

Transporting items from point A to Point B is a common occurrence for almost any type of business and is often accomplished by manpower. However, when the “items” that need to be moved are heavy, dangerous, or difficult to contain and need to be moved continuously in large quantities, a conveyor comes into play. The use of conveyors for material handling has been occurring since as far back as 1795, when basic conveyor systems were used to move grains a short distance. By definition, a conveyor is any piece of mechanical equipment that moves materials from one location to another. In day-to-day business, this could be a belt that is used to sort packages, items coming off a production line, or luggage headed to an airplane cargo hold. For industrial purposes, however, conveyors are much more specialized and must be able to withstand many different types of environments. As the name implies, material is dragged along the conveyor by either a single chain or multiple chains with a paddle. At many industrial plants, it’s crucial to be able to move bulk material quickly and reliably. Whether you’re dealing with cement, clinker, lime, coal, wood chips, phosphate, food waste, grains, or ash, a dependable conveyor is a must to keep things up and running. There are many different types of conveyors to choose from, and the best one for a given situation is usually determined by the type of material that needs to be conveyed and the distance it needs to move. One of the more popular options is a drag conveyor, which is sometimes referred to as a drag chain, drag flight, or en-masse conveyor.

As the name implies, material is dragged along the conveyor by either a single chain or multiple chains with a paddle. At many industrial plants, it’s crucial to be able to move bulk material quickly and reliably. Whether you’re dealing with cement, clinker, lime, coal, wood chips, phosphate, food waste, grains, or ash, a dependable conveyor is a must to keep things up and running. There are many different types of conveyors to choose from, and the best one for a given situation is usually determined by the type of material that needs to be conveyed and the distance it needs to move. One of the more popular options is a drag conveyor, which is sometimes referred to as a drag chain, drag flight, or en-masse conveyor. A bucket elevator is one of the most common types of industrial conveyors and is utilized by companies in a wide array of industries. When large quantities of bulk material need to be moved vertically in an efficient and reliable manner, a bucket elevator is often the best option. In this article, we will explain how exactly bucket elevators work and discuss some of the applications for which they are popular.

A bucket elevator is one of the most common types of industrial conveyors and is utilized by companies in a wide array of industries. When large quantities of bulk material need to be moved vertically in an efficient and reliable manner, a bucket elevator is often the best option. In this article, we will explain how exactly bucket elevators work and discuss some of the applications for which they are popular. Since 1927, Materials Handling Equipment (MHE) has been manufacturing custom bucket elevators for industrial plants throughout the United States. We are recognized as pioneers in several classes of conveyors, including mill-duty and cement-duty. While many other conveyor manufacturers offer cookie-cutter options, our bucket elevators are custom-manufactured to fit the space they will occupy and the application they will be used for. Additionally, we utilize special wear-resistant alloys and customized components, so our bucket elevators provide decades of reliable service in the most severe environments imaginable. In fact, many of our custom conveyors are still in service more than half a century after delivery.

Since 1927, Materials Handling Equipment (MHE) has been manufacturing custom bucket elevators for industrial plants throughout the United States. We are recognized as pioneers in several classes of conveyors, including mill-duty and cement-duty. While many other conveyor manufacturers offer cookie-cutter options, our bucket elevators are custom-manufactured to fit the space they will occupy and the application they will be used for. Additionally, we utilize special wear-resistant alloys and customized components, so our bucket elevators provide decades of reliable service in the most severe environments imaginable. In fact, many of our custom conveyors are still in service more than half a century after delivery. One of the most common types of conveyors you’ll find at industrial facilities is the bucket elevator. This style of conveyor is a workhorse for a variety of industries and can reliably and efficiently move large quantities of bulk material. They are used effectively in a wide variety of industries, including:

One of the most common types of conveyors you’ll find at industrial facilities is the bucket elevator. This style of conveyor is a workhorse for a variety of industries and can reliably and efficiently move large quantities of bulk material. They are used effectively in a wide variety of industries, including: