Drag conveyors and screw conveyors are popular options for bulk material handling in a variety of industries, and while both might be able to accomplish a company’s goals, they’re not always interchangeable options. Drag conveyors and screw conveyors both offer advantages and disadvantages, and often the best option depends on the type of material being moved.

Drag conveyors and screw conveyors are popular options for bulk material handling in a variety of industries, and while both might be able to accomplish a company’s goals, they’re not always interchangeable options. Drag conveyors and screw conveyors both offer advantages and disadvantages, and often the best option depends on the type of material being moved.

How Do These Conveyors Function?

Before we start outlining the potential benefits and drawbacks of drag conveyors and screw conveyors, let us establish how they function:

Drag Conveyors

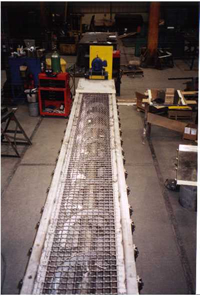

Drag conveyors move bulk materials through a channel using a single- or double-stranded chain of paddles, or “flights,” mounted to the chain. A drag chain conveyor utilizes a single strand of chain while a drag flight conveyor typically includes dual or double strands of chain with a flight mounted between the chains. They can have an open top or be fully enclosed, and they can handle inclines effectively. The ample amount of space between the paddles often allows for easy loading. Drag Conveyors can also be top or side loaded.

Screw Conveyors

Screw conveyors are similar to tubular drag conveyors in that they also move bulk materials through a tube or channel. This channel is referred to as a U-trough. A rotating auger, or screw, inside the tube pushes granular materials forward through the length of the tube. They’re most effective when horizontal and their use for inclines requires special efficiency factors to insure capacities are met.

Which Conveyor Fits Your Company’s Needs?

As was mentioned previously, the determining factor between utilizing a drag conveyor or screw conveyor is usually the type of bulk material that needs to be moved. Because the blade of a screw conveyor rotates directly through the material in the tube, it can grind material down and cause blend separation. Therefore, screw conveyors are not ideal for delicate products. However, they’re extremely effective for many semi-solid materials, including animal feed, boiler ash, municipal solid waste, and other free-flowing bulk materials.

By contrast, drag conveyors pull or push bulk materials with no tumbling or agitation. They simply “drag” the material along. This makes them ideal for materials that would be negatively impacted by particle degradation and blend separation. Drag conveyors are also a viable option if you need a greater capacity than a screw conveyor can deliver.

The No. 1 Choice for Heavy-Duty Conveyors

While you’re trying to choose between a drag conveyor and a screw conveyor for your plant, there’s one decision that should be easy. Materials Handling Equipment is the wise choice for any type of industrial conveyor, as we’ve been perfecting our manufacturing process since 1927. While many conveyor manufacturers offer standard models that lack modification, we deliver multiple types of screw and drag conveyors that are customized to meet the specific needs of our clients.

While you’re trying to choose between a drag conveyor and a screw conveyor for your plant, there’s one decision that should be easy. Materials Handling Equipment is the wise choice for any type of industrial conveyor, as we’ve been perfecting our manufacturing process since 1927. While many conveyor manufacturers offer standard models that lack modification, we deliver multiple types of screw and drag conveyors that are customized to meet the specific needs of our clients.

Materials Handling Equipment is also the industry leader when it comes to conveyors that can perform reliably in extreme conditions. Our drag conveyors and screw conveyors are manufactured using heavy-duty components that can withstand severe abrasion, corrosion, and temperature. One of the byproducts of our dedication to ensuring the quality and durability of our products is conveyors that are still performing dependably more than 50 years after they were delivered.

Learn More About Our Drag Conveyors & Screw Conveyors

Make a reliable choice for your company’s needs. Contact Materials Handling Equipment today if you’d like to learn more about the custom conveyors we offer to businesses in a wide array of industries.