Custom-Manufactured Drag Chain Conveyor Systems

If you’re in the market for a drag chain conveyor that can move bulk materials quickly and efficiently, don’t settle for a system that doesn’t meet all of your specific needs. Materials Handling Equipment (MHE) engineers, manufactures, installs, and services custom conveyor systems that are designed to handle a variety of applications, and we’ve been a leader in the industry since 1927. Because of our experience serving many different industries, we have a unique combination of knowledge and expertise that helps us meet our clients’ unique demands.

How Does a Drag Conveyor Work?

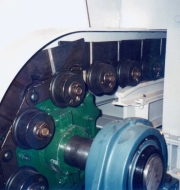

Drag conveyors offer unmatched efficiency thanks to their simple design. They drag bulk materials through a channel or trough using paddles or “flights” that are attached to a single chain or multiple chains. They can be partially or fully enclosed, and their large paddles make it easy to convey large quantities of material in a short period of time while using minimal power. Drag conveyors are usually horizontal but can be inclined if special paddles are used, and they are easy to load because of the gaps between the paddles.

Able to Withstand Extreme Conditions

Nobody makes drag chain conveyor systems that are better equipped to handle extreme conditions than MHE. We utilize wear-resistant alloys and extra heavy-duty chains and mechanical components to provide for a longer life, and the flexible design and customized features we offer can greatly improve the quality of the product. In fact, many of our custom drag chain conveyors are still operating reliably more than a half century after initial delivery. What’s more, we offer the largest selection of models that can hold their own when being used for high-temperature, abrasive, and corrosive applications. Our drag conveyors offer capacities to 500 TPH, are able to withstand temperatures up to 2,500 degrees, and can be up to 20 feet wide, 300 feet long, and inclined to 45 degrees.

Drag Conveyor Uses

Drag conveyors are ideal for dry material that flows easily, such as ash, wood chips, grains, and cement. They are commonly utilized in the agriculture, chemical, construction, cement, and mining industries. The drag chain conveyors that MHE manufactures also come in a variety of classifications, including:

- Siftings conveyors

- En-masse conveyors

- Bottom and fly ash conveyors

- Submerged chain conveyors

- Wood chip reclaimers

- Deslaggers

- Clinker conveyors

- Sludge cake conveyors

- Grit collectors

Get Started Today

While many drag conveyor manufacturers offer “one size fits all” options, when you partner with us we’ll provide a conveyor that’s customized for your needs. We’ll ensure it fits your plant perfectly, and we’ll train your employees on its safe operation. If you ever experience an issue, our emergency response team will be standing by to help.

If you would like additional information about the heavy duty drag chain conveyor systems Materials Handling Equipment custom manufactures, contact us today.