Improve Your Plant’s Efficiency with a Custom-Engineered Tubular Drag Conveyor From Materials Handling Equipment

A tubular drag conveyor is an excellent option if you need to move bulk material a long distance in a safe and efficient manner. And, because of their enclosed nature, tubular conveyors are a great choice when you need to avoid dusting or contamination. If your company is in need of a custom tubular conveyor system that is durable enough to perform efficiently in any environment, look to the conveyor experts at Materials Handling Equipment (MHE).

Simply put, no other manufacturer can match the experience MHE brings to the table. We’ve been custom-engineering heavy-duty conveyor systems since 1927, and we have the knowledge and expertise needed to solve your bulk material conveyance dilemmas. The conveyors we manufacture have been used by major companies throughout the world from a wide variety of industries, including agriculture, chemical, mining, steel, cement, and more.

Custom-Manufactured Tubular Drag Conveyors That Are Built to Last

When you choose MHE for your tubular drag conveyor, you can expect a system that is custom-engineered to provide the utmost efficiency and handle your plant’s specific needs. Our drag conveyors offer:

- Greater reliability due to custom-engineered components

- A longer service life thanks to extra-heavy-duty chains and mechanical components

- Dependability in high temperatures and extremely abrasive or corrosive environments

- Easy maintenance from the top and ends because of unique access features

Additionally, MHE drag conveyors offer industry-best specification options, as they can be as wide as 20 feet, as long as 300 feet, and can have as much as a 45-degree incline.

How Does a Drag Conveyor Work?

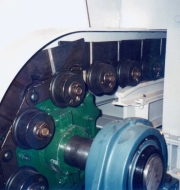

As the name suggests, drag conveyors “drag” bulk materials through a channel using a motorized single- or double-stranded chain of paddles or “flights.” They can be partially or fully enclosed and either inclined or horizontal, depending on the type of paddles being used. Top-loading of drag conveyors is easy and efficient because of the space between the paddles, and they usually don’t require as much floor space as other conveyor types.

A tubular drag conveyor system can be one of the most efficient types of industrial conveyors, as it can move large quantities of material quickly using minimal power. Another type of drag conveyor—called an en-masse conveyor—utilizes a single chain with paddles on both sides and is able to move larger quantities of bulk material.

Tubular drag conveyors are popular in the chemical, power and utilities, and construction industries and can move a wide variety of materials, including:

- Ash

- Cement

- Clinker

- Coal

- Food waste

- Grains

- Lime

- Phosphate

- Wood chips

Contact Materials Handling Equipment today to learn more about the heavy-duty tubular drag conveyor systems we offer. We’ll be happy to visit your plant to better understand your needs so we can provide a custom-engineered solution.